Elevate Your Manufacturing with Robust Reliability and Predictable Performance

Welcome to SEYMOUR Advanced Technologies, where we guide businesses to achieve predictable, high-performance automation. We understand that in today's demanding manufacturing landscape, the goal isn't just to automate tasks, but to guarantee reliable outcomes and eliminate uncertainty. Our commitment is to move beyond the hope that a product works as designed, by engineering solutions rooted in rigorous testing and applied reliability.

Choosing SEYMOUR Advanced Technologies means partnering with a company that provides custom automation designed to deliver predictable results and an unmatched competitive edge. Our deep expertise and vertically integrated approach provide practical, actionable solutions rooted in real-world production experience.

Guaranteed Reliability:

We uphold stringent reliability and performance demands, ensuring consistent, long-term operation. Our systems are built to perform reliably, consistently, and within strict specifications, eliminating guesswork.

Predictable Outcomes:

Through comprehensive testing and data analysis, we provide certainty in performance, reducing deviations and minimizing errors. Our systems understand the job, track the process, and report on performance in real time.

Reduced Downtime:

Our proactive approach, including predictive diagnostics and machine learning, allows us to anticipate and address potential issues before they lead to costly downtime.

Regulatory Compliance:

We build in the ability to trace every part and log all data for highly regulated industries like medical devices, aerospace, and defense, providing comprehensive documentation to support validation efforts.

The SEYMOUR Advantage: Beyond Ordinary Testing

Choosing SEYMOUR Advanced Technologies means partnering with a company that offers more than just automated machines. We provide:

01

Design Qualification (DQ):

This initial phase meticulously documents design specifications to meet cGMP requirements, user needs, and regulatory standards. It includes performing risk assessments (e.g., FMEA) and reviewing material certifications to identify potential failure modes and implement mitigation strategies.

02

Factory Acceptance Testing (FAT):

Before shipment, the machine undergoes rigorous testing at our facility. This involves:

◦ Functional Testing: Verifying all mechanical, electrical, and software components operate as intended.

◦ Performance Testing: Measuring cycle times, throughput, and accuracy to meet design specifications.

◦ Software Validation: Testing all software functions, including data acquisition, control algorithms, and user interfaces.

◦ 3D Vision System Calibration and Verification: Ensuring the 3D vision system accurately measures and inspects parts with micron-level accuracy.

◦ Robotic Accuracy and Repeatability Testing: Verifying the robot's ability to perform precise movements and assembly tasks, often achieving +/- 5-micron repeatability.

◦ Safety Testing: Verifying all safety interlocks and emergency stops.

◦ Part Verification Testing: Running known good and bad parts to confirm proper operation of verification systems. All testing is meticulously documented, and deviations are addressed before approval for shipment.

03

Site Acceptance Testing (SAT):

Upon installation at your facility, SAT ensures correct operation in the intended environment, including re-testing critical functions, integration testing with existing systems (MES, ERP), and environmental testing.

04

Installation Qualification (IQ):

The installation process is documented, verifying that the machine is installed according to manufacturer specifications and instrument calibrations.

05

Operational Qualification (OQ):

This demonstrates that the machine operates within its specified ranges, testing critical process parameters (e.g., temperature, pressure, speed), alarm/interlock functions, and data acquisition/logging systems. It also verifies the machine produces conforming parts.

06

Performance Qualification (PQ):

This phase demonstrates that the machine consistently produces products meeting predetermined acceptance criteria, involving multiple production batches to verify process capability and product quality. It confirms the functionality of part error detection systems and the machine's robust product assembly.

07

Ongoing Monitoring and Maintenance:

Post-PQ, a schedule is established for continuous monitoring, calibration, and preventive maintenance, with all events fully documented.

Beyond Hope: The Power of Applied Reliability & Rigorous Testing

We don't simply assemble machines; we engineer complete systems that understand the job, track the process, and report on performance in real time. This foundational idea empowers the end user, allowing for more informed decision-making and minimized downtime. Our systems become a central source of truth for quality and performance, providing a living database of performance metrics and process knowledge.

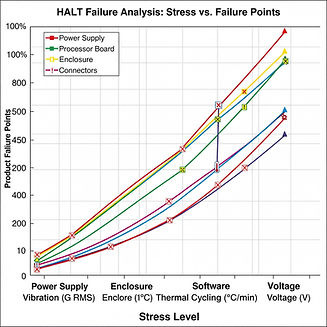

Our robust and transparent project management framework encompasses critical stages, ensuring highly accelerated life-cycle testing, including methodologies such as vibrational testing, fluctuating heat and cold cycles, and elevated stress pass design. We adhere to strict cGMP testing practices to ensure consistency, quality, safety, and efficacy. By integrating metrics like Mean Time To Failure (MTTF) and Mean Time To Repair (MTFR), we proactively identify and address potential issues, minimizing downtime and maximizing product uptime.

The SEYMOUR Advantage:

Our Competition Diminishing Toolkit for Guaranteed Performance: Separating you from the competition.

01

Advanced Simulation & Modeling:

Our multidisciplinary engineering team leverages advanced computer modeling and simulation, including CAD (Computer-Aided Design) and FEA (Finite Element Analysis), to optimize system performance and ensure reliability and effectiveness from the outset. We provide comprehensive 3D models and virtual walkthroughs.

02

Micron-Level Verification

We integrate cutting-edge 3D vision systems utilizing technologies such as structured light, stereo vision, and time-of-flight to deliver a wealth of depth information for precise measurement, surface reconstruction, and robot path planning. This enables us to detect subtle defects invisible to 2D systems and achieve micron-level accuracy in assembly, inspection, and measurement, often with resolution down to 0.25 microns and +/- 5-micron repeatability. We employ advanced data manipulation techniques like noise reduction, filtering, and point cloud registration.

03

Machine Learning & AI-Driven Analytics:

We implement machine learning to automatically track data, learn from previous cycles, and adjust for future cycles, ensuring perfect alignment and assembly. Our systems provide real-time performance data, trend analytics, and predictive diagnostics, allowing clients to proactively prevent issues and make each production cycle smarter than the last.

04

Comprehensive Data Capture & Monitoring:

We enable superior process data capture and enhanced tracking and tracing capabilities. Our systems meticulously monitor critical elements such as force, torsion, velocity, acceleration, time, pressure, volume, weights and masses, translation, and rotation, ensuring product consistency and predictability.

At SEYMOUR Advanced Technologies, we meticulously manage every phase of your project, ensuring a seamless journey from initial concept to a fully operational and validated solution. Our approach ensures that successful automation hinges on clear communication, meticulous planning, proactive risk management, and unwavering attention to detail throughout the entire project lifecycle.

The SEYMOUR Advantage: Precision and Speed, Built In-House

Our unique vertically integrated manufacturing capabilities, encompassing both additive manufacturing (including 3D printing in both metal and plastic) and subtractive manufacturing (utilizing CNC mills and lathes), provide a significant advantage in delivering reliable systems. By controlling every stage of the production process in-house—from design and manufacturing to production and quality assurance—we:

01

Ensure Uncompromising Quality:

Maintain rigorous quality control throughout every stage, ensuring adherence to the highest industry standards.

02

Facilitate Rapid Iteration

Leveraging our unique vertically integrated manufacturing capabilities, we quickly adapt designs and implement changes based on testing and feedback, enabling rapid iteration and design refinements.

03

Accelerate Project Timelines:

Get critical components and functional prototypes fabricated quickly, bypassing external lead times and speeding up development cycles. Our rapid prototyping approach allows us to go from design to prototype in a matter of hours, delivering custom systems in as little as five months, with functional prototypes in as fast as 2 hours.

Ready to experience the SEYMOUR Advanced Technologies difference?

Contact us today for a consultation. Ready to optimize your automation investments with a data-driven approach that ensures predictable outcomes and unwavering reliability?

Contact Team SEYMOUR

Experience today the SAT difference – where cutting-edge technology meets unparalleled project management expertise and the speed and flexibility of in-house vertical integration, supported by a team of dedicated professionals at every stage.

_edited.png)

%20(1)_edited.png)